Shipping country

Wood Species

News

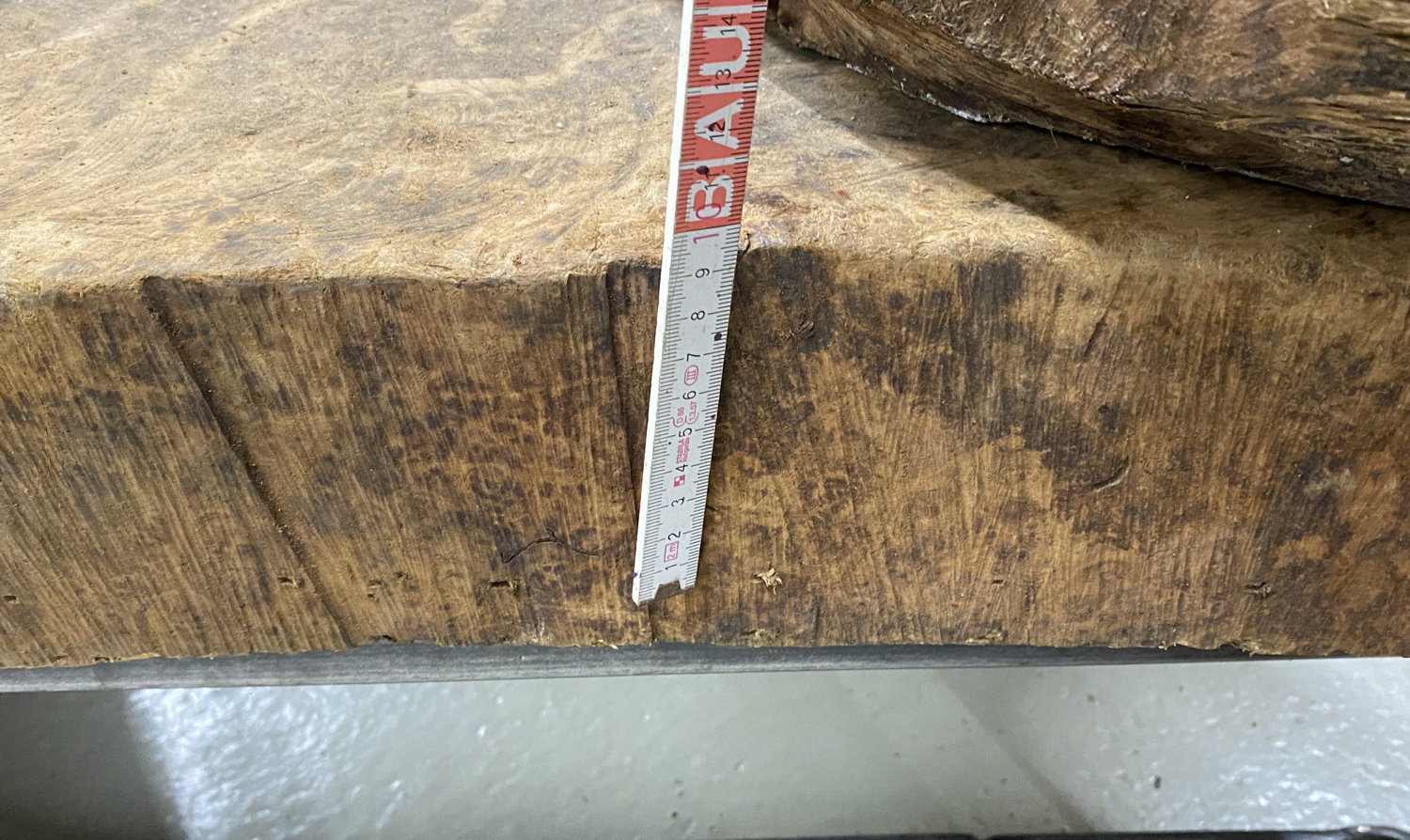

With Christmas already on December 19, a large fresh delivery of several tons of olive wood finally arrived at our premises on December 19 after a long journey lasting several weeks.

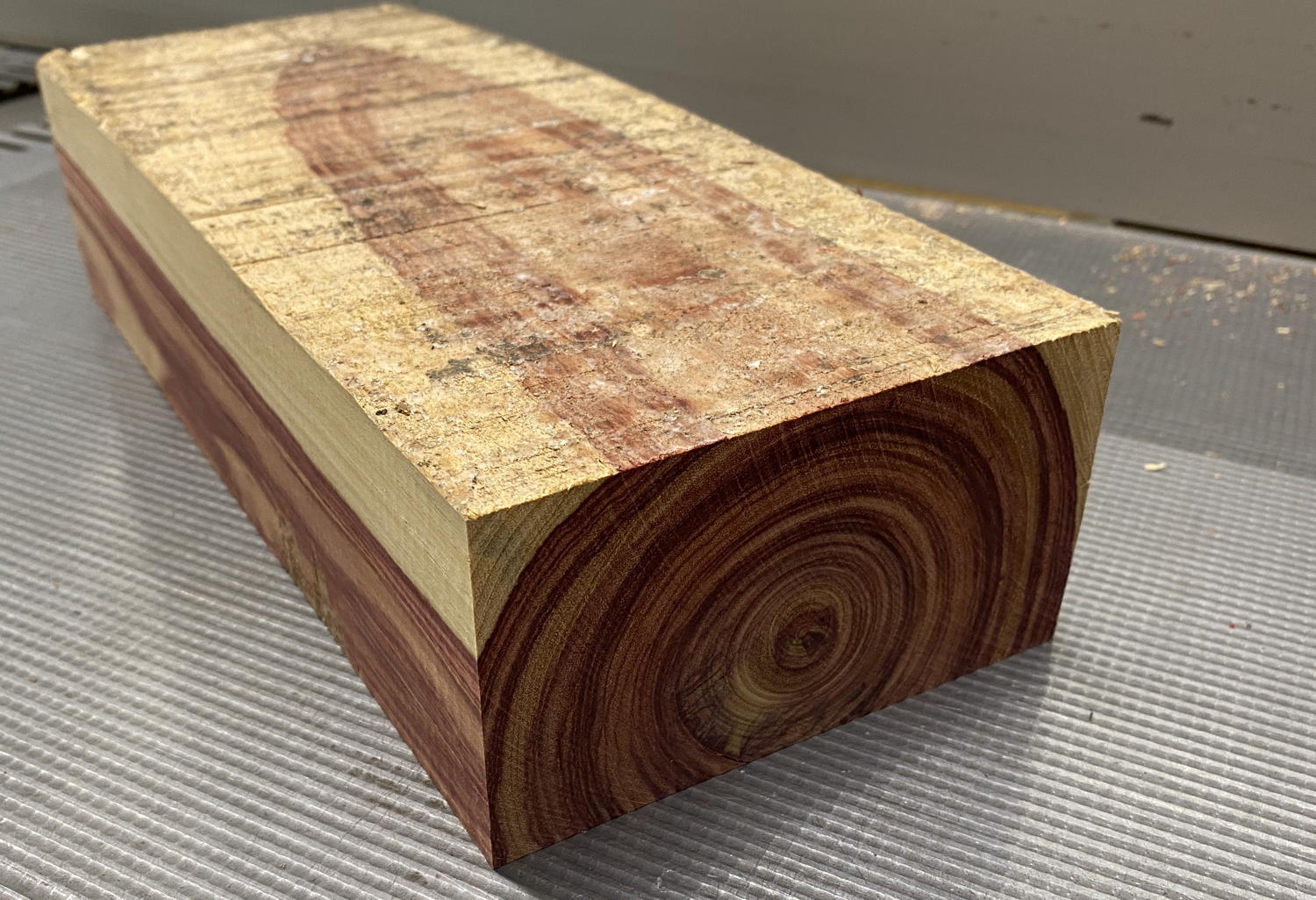

We were finally able to unload a large shipment of olive wood scantlings here again, and the joy of unpacking the pallets and stacking them on the shelves is indescribable: the wood smells wonderfully aromatic, is very pleasant to the touch, and above all, it never ceases to amaze with its incredible range of grains, colors, structures, and growth characteristics: this is more incredible than with any other wood! Particularly beautiful scantlings from ancient wild olive trees that no longer bear fruit are so beautiful that many are set aside and, after proper drying, will go on sale as particularly beautiful and extremely fine and wildly grained premium scantlings.

The wood comes from a special variety of olive tree, the extremely slow-growing and fine-grained Lianolia Kerkyra, which is unique among all other olive trees in the Mediterranean region. Its wood is clearly the finest, most finely grained, most beautiful, and most wildly grained olive wood to be found in the entire Mediterranean region.

During their reign from the 9th century to the end of the 18th century, the members of the Republic of Venice offered a premium for olive trees of this imported variety as early as the 16th century in order to secure their own supply of olive oil for lighting purposes—ultimately producing large quantities of olive oil, including for the Vatican. According to historical data, exports of lamp oil shortly before 1800 amounted to approximately 70,000 barrels, each containing approximately 158 liters. The light for the lamps in Veneto thus grew on the Ionian Islands. As a result, the wine culture that had prevailed until then disappeared, and as a consequence, entire forests of olive trees covered the Ionian Islands in the Mediterranean.

The wood comes from a special variety of olive tree, the extremely slow-growing and fine-grained Lianolia Kerkyra, which is unique among all other olive trees in the Mediterranean region. This olive wood is in no way comparable to the ‘normal’ olive wood that grows in Spain and Italy. In Italy in particular, olive trees are pruned for high wood yield and planted and processed specifically for wood production. Their wood grows very quickly thanks to generous fertilization and optimal irrigation, providing the best possible growing conditions. However, it has an uninteresting grain, is much coarser and softer, and is essentially an industrially manufactured product for flooring and kitchen utensils. There is a world of difference between this turbo wood and our Venetian olive wood!

We have posted a number of special offers in our olive wood section today, because we will need space in our shelves for many thousands of new scantlings!

Ebony has been one of the most important woods in our range since the beginning of our precious wood trade, and we always strive to have a large quantity of this expensive wood in stock. In addition to a very large inventory of finished cuts in fixed sizes for instrument makers, woodturners, woodwind instrument makers, billiard cue makers, for fingerboards, piano keys, knife handles, fine writing instruments, and art objects such as sculptures, chess pieces, and fine walking sticks, we also always have a large quantity of sawn timber in stock so that we can continuously produce and deliver custom-sized cuts. Our range of old, well-seasoned ebony scantlings in particularly large dimensions, such as 400 x 100 x 100 mm, which are available for immediate delivery, is probably unique worldwide.

To this end, we constantly store several tons of this black gold here. However, much of this freshly purchased wood must be carefully stacked on slats in our specially air-conditioned storage rooms for several years so that air can reach the wood from all sides and it can dry slowly and continuously under constant monitoring. This ensures that our customers always receive only dry ebony of the highest quality.

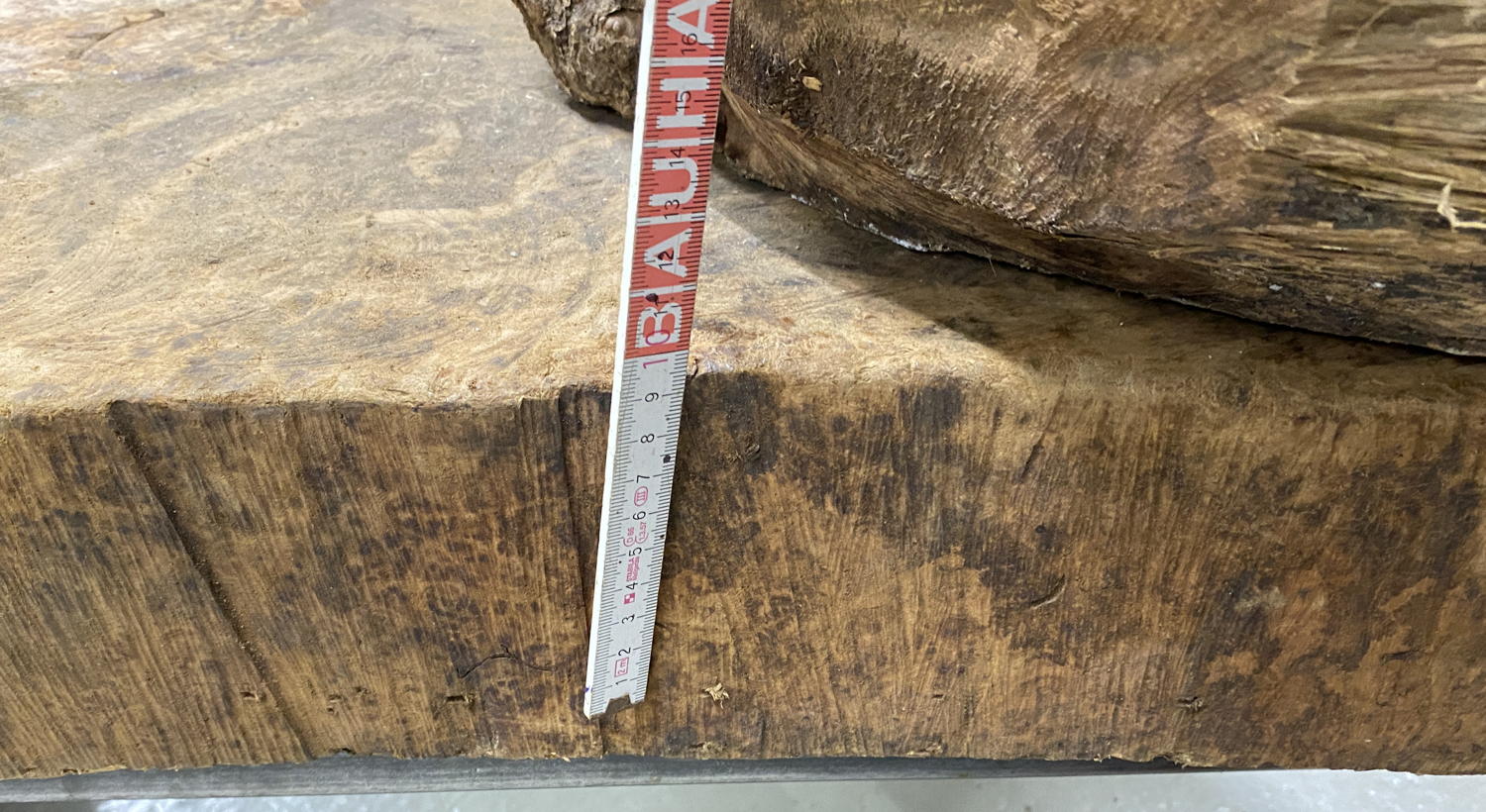

We have just stored another two tons of fresh ebony, which now has to be carefully monitored as it dries so that, in the best case scenario, it will be dry enough in two or three years to be worked with without the risk of cracking. As you can see, this is an investment in the future that, in addition to patience and sufficient capital, also represents a reassuring stability in value.

This wood has been on the CITES list since 2017 and can only be traded with certificates of origin that serve to protect this valuable wood. As this wood only grows endemically in northern Mozambique and southern Tanzania, there are no alternative areas with these trees. In addition, violent clashes between the army and armed fighters have been taking place in this region for years, making legal export even more problematic. Export ports have been temporarily occupied by jihadists, all of which makes it almost impossible to source good tonewood scantlings from Mozambique, forcing instrument makers to resort to substitute woods, which many musicians and instrument makers consider inferior. After lengthy preparations and negotiations, we have now been able to purchase this small batch of old tonewood blanks. CITES permits have been obtained, and our customers can now purchase that was imported years ago.

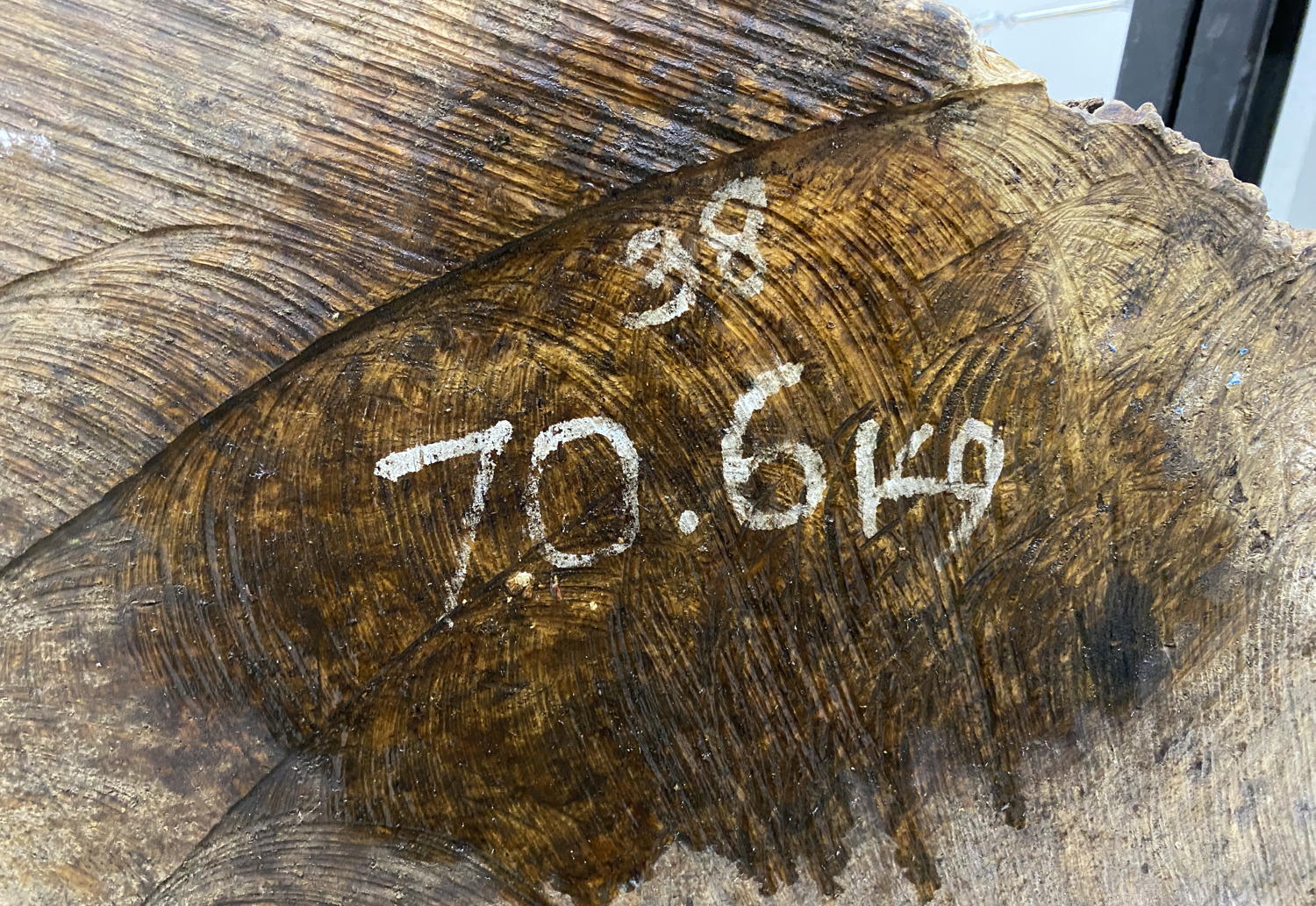

Only very rarely will you be lucky enough to find and be able to buy a really old stock of brazilian tulipwood that has now become quite rare. In this case, we were lucky enough to be able to buy a very special, truly ancient half-trunk from the dark depths of an old timber merchant alongside some other, quite young, beautiful pieces of tulipwood (Dalbergia decipularis): the trunk has absolute veneer quality, is very fine and evenly grained and has the much sought-after deep red intense color, with virtually no defects such as rotten spots or large cracks on the trunk, and it betrays its age by the way the raw trunk was processed with an adze in the forest after felling. Such valuable timber must be cut into clean lengths immediately after felling, and in order to prevent the expensive wood from cracking, these logs are usually split or sawn in half on the felling site, and then the most important thing of all takes place: all sapwood must be finely and carefully removed from the heartwood.

The sapwood has a completely different density and, if it were to remain on the trunk, its completely different shrinkage behavior would certainly cause it to tear the heartwood deeply during drying. A long time ago, therefore, such sapwood layers, which can be several centimeters thick in tulipwood, were carefully and conscientiously removed by hand with an adze or crosscut axe. This half-trunk shows exactly such traces of an adze; the typical, slightly rounded blade of this tool has left characteristic marks on the block, and this is probably one of the reasons why this piece has nearly no cracks. The second, adjacent half log is significantly younger, its sapwood has been roughly removed with three saw cuts, and so this log also has several cracks in its heartwood. The most difficult question is now: is it allowed to saw up such a special piece of rosewood just like that? And what's more, can it be scattered all over the world in small pieces by selling it in our store? As always, a decision is very difficult for the owner, and it will certainly take quite a while before there is a clear decision on this matter...

This extremely hard wood, which is rarely found in our latitudes, is something special: it is very strongly marbled, has a light yellowish basic color and is interspersed with clearly contrasting dark brown stripes. It grows in Dutch Guyana, Surinam and even there only very sporadically in large stands of other trees. As it is rare and highly sought after, the wood is not always easy to obtain, but we have managed to find and buy a somewhat larger quantity of very high quality wood from an old stand. The recurring problem with this wood is the often sudden cracks, knots or defects in the middle of the wood, which clearly determine the quality. This old batch of Serpentwood, which is also known as Angelim Rajado or in Surinam as Surinamse Bostamarinde, is of surprisingly good quality, it has very few of these typical defects and also has a good and fine grain. We are delighted to be able to offer this rare specialty to our customers all over the world!

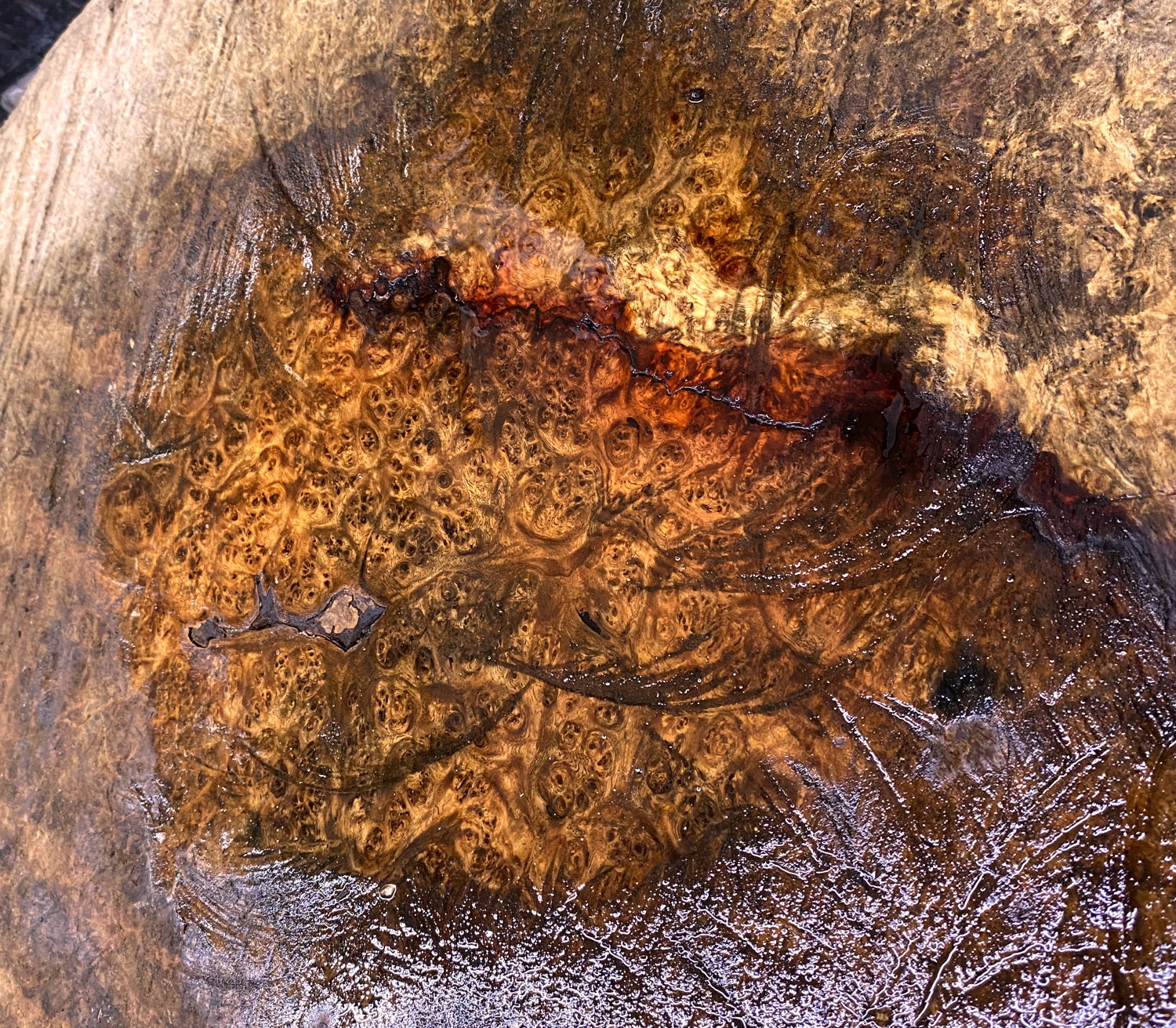

For the second time this year, we were able to get hold of a large quantity of beautiful and thick amboina wood, the first smaller quantity was of such beautiful and good quality that we also bought up the rest in its entirety, no, we almost had to buy this wood. Such large slabs with a fine, three-dimensional grain are an expensive but very rare rarity on the market and exactly the kind of fine wood that our trade is known for and that we sell time and time again. See the photos and share our joy!

It is not every day that a timber merchant can be as happy as on these days in March: after a long journey, a small batch of Tasmanian Blackwood arrived here with the first sunny days of the year, which is actually native to Australia, but can also thrive in other places in the world under favorable climatic conditions. The Acacia melanoxylon tree produces a very good dark wood that has good properties and also has an attractive chocolate brown color, it is fine-pored and also has a very beautiful natural luster. Blackwood is much sought after for furniture making, interior fittings, musical instruments, gunstocks and turned objects, where it is highly valued. The term blackwood is somewhat misleading, as the wood is not really black. Because of its shiny, golden-brown grain, it is used as a sustainable alternative to the closely related Hawaiian koa (Acacia koa). Although koa woods with a particular coloration and strong curly growth are more common, the two types of wood are virtually indistinguishable.

The tree has been newly planted and thus introduced in some regions of the world; it can be found as an ornamental and shade tree or on plantations for timber production - and in many areas the hardy trees have become an invasive species. In any case, we are delighted to have another beautiful and special type of wood in our range.

We were all the happier when this small quantity reached our trade, as it is very rare to find anything like it, and to be able to buy such wood from the wood-crazy sellers in Finland at a reasonably realistic price requires a great deal of luck and trust.

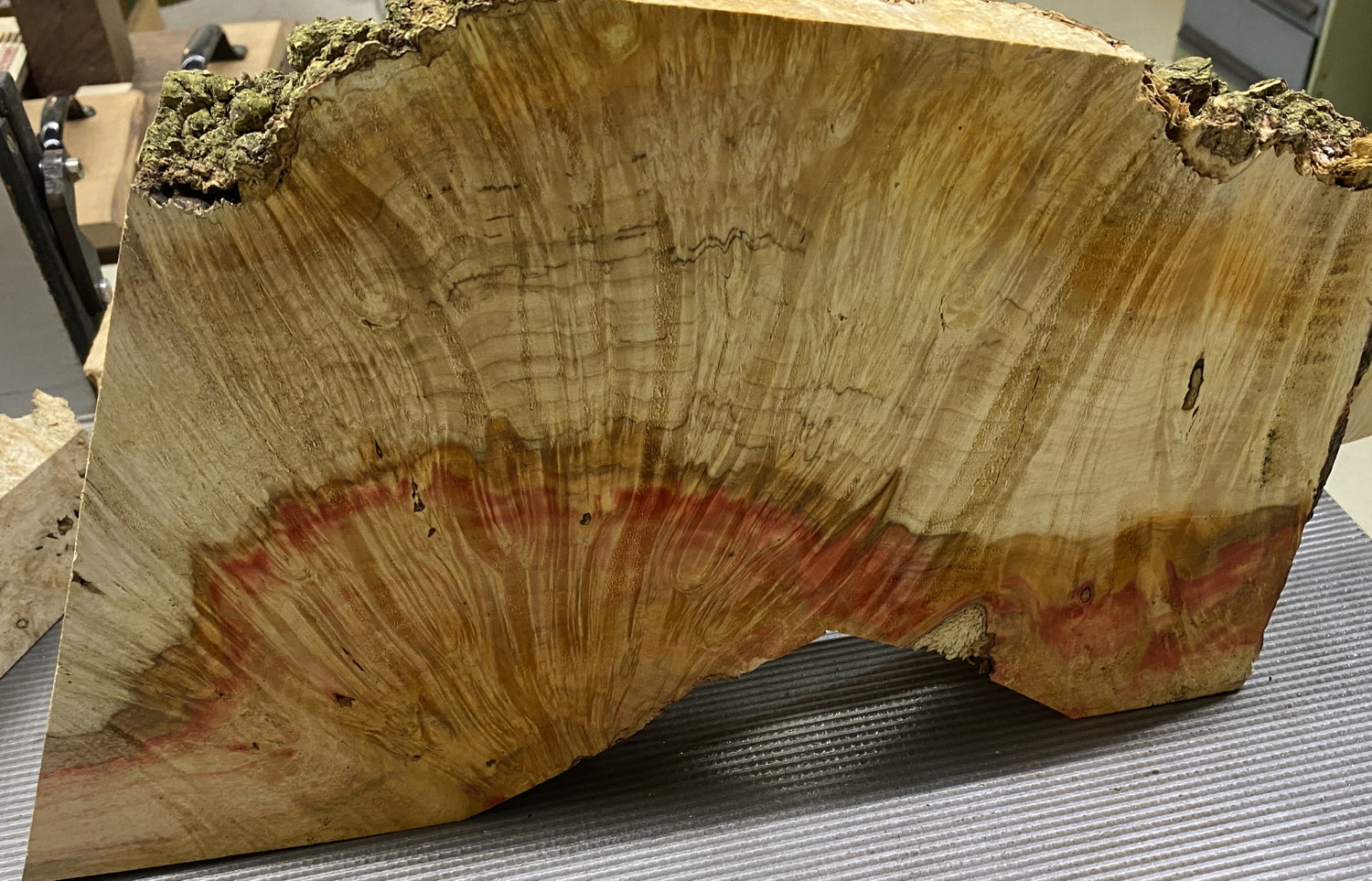

The special feature of ash maple burl is a unique, often fiery red color inside the trunk. This discoloration occurs as the tree tries to defend itself against invading fungi and produces these unusual colors, which can be clearly seen with lines of defense of the healthy wood against fungi and other wood-destroying parasites. In the case of the tree from which these beautiful pieces of burl wood comes, it was as often can be seen: the entire trunk was completely decomposed on the center, only a 15 - 20 cm thick layer of the finest burl wood supported the whole tree, and as a result of a storm this old tree then fell this year.

We were the lucky beneficiaries of this tree fall, the particularly beautiful burl wood is now drying in our warehouses and will probably be dry enough next year to be available in our webshop.

Such a discovery is often like a journey back in time, because you uncover treasures that were nothing so special some fifty years ago, but are now a real rarity that is rarely offered for sale and even more beautiful.

That's what happened to us with this find in France: a few very large, very thick and very dusty slabs of an initially unknown burl wood were found there, and careful attempts at planing revealed a beautiful grain, but what kind of wood it was initially remained in the dark. However, once the smaller boards had been cut in half in width to fit over the jointers width of 45 cms, the joy was great; a beautiful warm golden-yellow wood color emerged, and the grain had a strong three-dimensional effect, looking unreal for a flat surface. With a little white spirit sprayed on, you can get an idea of the deep structure and color that a finished product made from this wood will one day have. A scientific determination of the wood then revealed that it belongs to the Pterocarpus family, to which the red Amboina burl wood also belongs, but in this case it is a wood known as golden Amboyna or Moudui burl, it comes from South East Asia, Thailand and Laos are its natural growth areas. We don't need to emphasize how happy this find and its beauty make us, and we are also delighted to be able to offer this unique feature to our customers all over the world!