Shipping country

Wood Species

Ebony- which is for later...

20.07.2022

Recently, several tons of ebony have moved into our warehouse, and as beautiful and promising as this wood is, we will have to forget about this lot after carefully cleaning and sealing the end grain, because the wood will take quite a few years to dry. Ebony is expensive, scarce and bitchy when fresh, so hard and dense that even in thinner thicknesses it takes years to release the water it contains slowly enough to prevent cracking.

Technical drying in kiln works with ebony, but it is very slow, highly energy-intensive and not always as successful as the old-fashioned way of slow air drying.

We have been taking the slow and expensive route of air drying here since 2007, which ultimately produces the best quality wood, and for that you have to have a great deal of patience and money.

Any business economist will explain that warehouses must turn over as quickly as possible in order to make the maximum profit. What a nonsense that does not apply to the trade with expensive precious woods!

For our customers this means that they can always rely on air-dried woods that are unproblematic to work with, do not crack, hardly warp and thus represent the highest quality class.

In our storage rooms, temperatures of approx. 17 - 23 degrees with approx. 50-60 % relative humidity prevail in summer and winter, the warehouse is heated very moderately in winter and due to the meter-thick walls of the former cold storage room, the course of climate is very constant with little changes. This, of course, greatly benefits the drying of such valuable woods as ebony, rosewood and olive, and you, the customer, benefit from the owner's more than 30 years of experience in the wood trade.

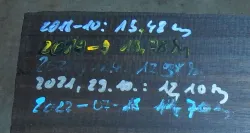

We usually track the drying of woods by regularly weighing individual marked pieces from a lot. From the course of this weighing data, it is then easy to see when the weight loss becomes slower and slower and thus a balance moisture content with the environment is reached. As an example, we show here a small slab from a lot of ebony purchased in 2018 from Nigeria. This piece still weighed 15.48 kg when it entered the warehouse, then after just under a year it weighed 13.78 kg, in April 2020 it was still 12.58 kg, then in 2021 in October it was still 12.10 kilos, and now in July 2022 it is still 11.70 kg. An overall weight loss of approx. 3.8 kg. The Gann Hydromette indicates 10.6%, and thus the wood from 2018 can now be processed without any problem.

Technical drying in kiln works with ebony, but it is very slow, highly energy-intensive and not always as successful as the old-fashioned way of slow air drying.

We have been taking the slow and expensive route of air drying here since 2007, which ultimately produces the best quality wood, and for that you have to have a great deal of patience and money.

Any business economist will explain that warehouses must turn over as quickly as possible in order to make the maximum profit. What a nonsense that does not apply to the trade with expensive precious woods!

For our customers this means that they can always rely on air-dried woods that are unproblematic to work with, do not crack, hardly warp and thus represent the highest quality class.

In our storage rooms, temperatures of approx. 17 - 23 degrees with approx. 50-60 % relative humidity prevail in summer and winter, the warehouse is heated very moderately in winter and due to the meter-thick walls of the former cold storage room, the course of climate is very constant with little changes. This, of course, greatly benefits the drying of such valuable woods as ebony, rosewood and olive, and you, the customer, benefit from the owner's more than 30 years of experience in the wood trade.

We usually track the drying of woods by regularly weighing individual marked pieces from a lot. From the course of this weighing data, it is then easy to see when the weight loss becomes slower and slower and thus a balance moisture content with the environment is reached. As an example, we show here a small slab from a lot of ebony purchased in 2018 from Nigeria. This piece still weighed 15.48 kg when it entered the warehouse, then after just under a year it weighed 13.78 kg, in April 2020 it was still 12.58 kg, then in 2021 in October it was still 12.10 kilos, and now in July 2022 it is still 11.70 kg. An overall weight loss of approx. 3.8 kg. The Gann Hydromette indicates 10.6%, and thus the wood from 2018 can now be processed without any problem.